The Wize Company for structural steel detailing services in USA according to the constantly changing needs of modern construction and engineering industries. Our proficiency facilitates direct cooperation between the collaborators in design, engineering, fabrication, and contracting, with a view to minimizing errors, optimizing material usage, and improving project efficiency. We target critical pain points affecting the industry: design inconsistency, wastage of materials, and coordination gaps, and we provide accurate, high-quality steel structural design services in USA that allow for easy fabrication and erection.

Our approach systematically resolves typical design and implementation conflicts, ensuring effective execution and quality outcomes. We achieve this through:

High-precision detailing minimizes errors and costly rework.

Full coordination between architects, engineers, and fabricators.

Optimized workflows for quicker project completion.

Smart detailing that will help reduce material wastage and labor.

Expertise in several geographies across project scales.

At The Wize Company, we provide precise, cost-effective steel detailing services designed to improve efficiency, reduce waste, and ensure seamless coordination in your projects:

Our team has had considerable exposure in a variety of domains and has worked in the following areas:

The Wize Company for structural steel detailing services in USA according to the constantly changing needs of modern construction and engineering industries.

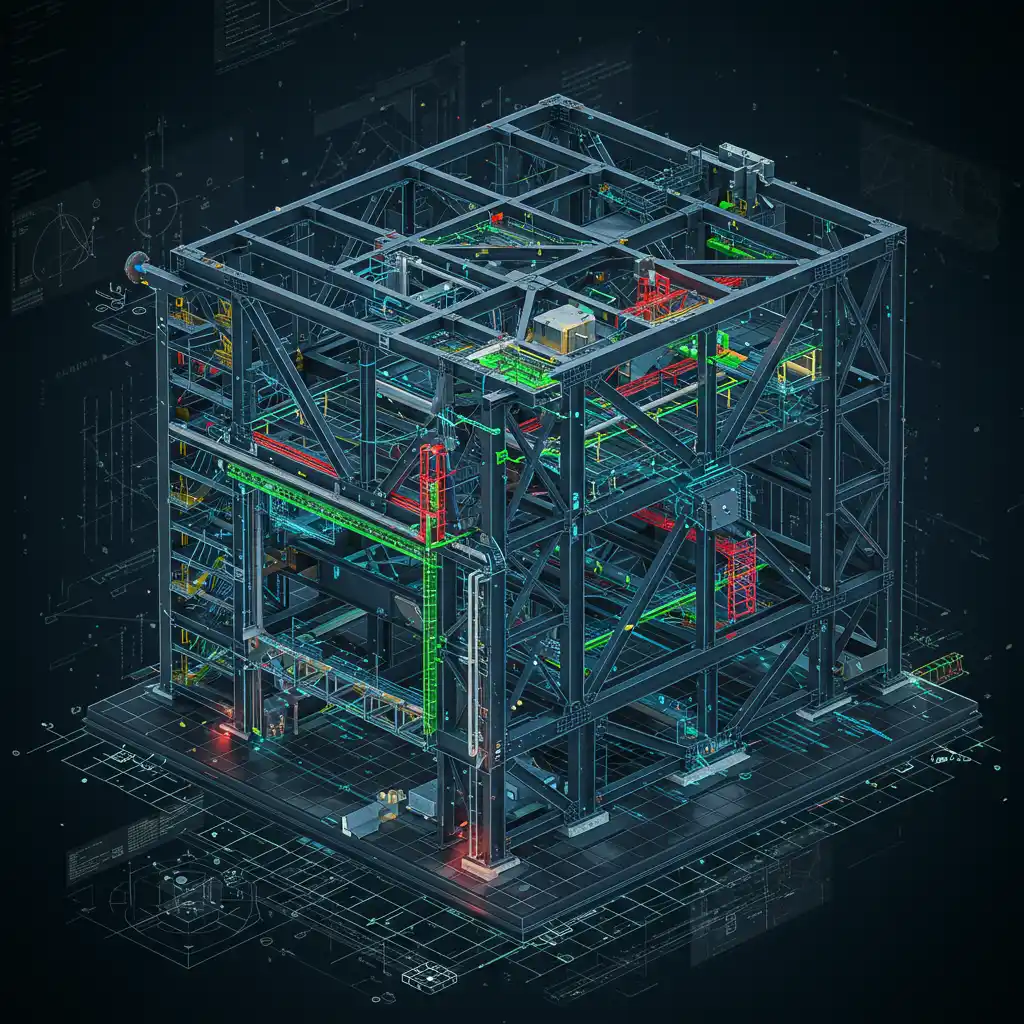

Increasing accuracy and collaboration with intelligent 3D modeling and clash detection.

Providing precision drawings for timely assembly and fabrication.

Facilitating trouble-free installation through well-defined erection plans and connections.

Providing maximum material utilization and cost estimation for efficient procurement.

Ensuring precise bolt placement for safe and stable design of steel structure construction.

We ensure compliance and structural integrity in all projects by aligning our practices with international industry standards and codes:

At Wize Company , we are committed to delivering precision-driven steel detailing services that empower our clients with accuracy, efficiency, and cost savings.

To ensure a consistent and repeatable process, we have developed comprehensive written procedures to manage design, detailing, and deliverables throughout the project lifecycle.

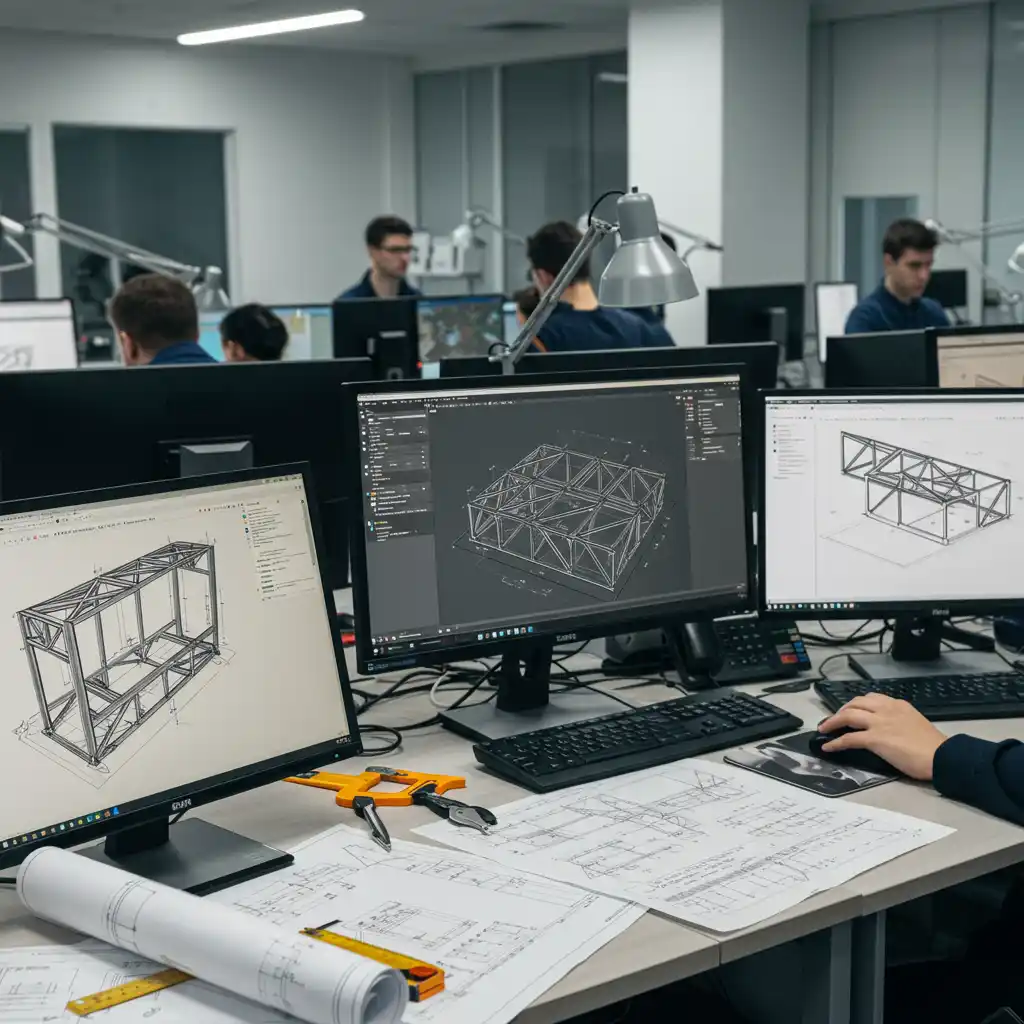

We utilize Tekla and SDS2 for detailing and other measurements for structural steel detailing, steel structure building design.

Certainly, we are open to any step size projects and have specialized solutions for each. We are specialists in structural steel detailing.

We assure the quality by complying with global standards and continuity checks conducted throughout the term.

Yes, our solutions are customized to meet the needs of each client.

We follow AISC, BS, CISC, and ISO for quality and compliance.

Our tools focus on reducing errors and achieving better work on any project.

Structural steel is a really handy and tough material that’s used a lot in building things. It’s super strong, can last for ages, and you can get parts ready before you need them. It’s great for lots of things. But to really make the most of it, you need the right detailed plans. They also ensure the safety and integrity of the final structure. This is where steel detailing comes in.

Steel detailing is like a translator. It turns the engineer’s dream into something the factory can make. It changes complex plans into simple instructions for every piece of steel.

These instructions are detailed maps. They show the exact size and shape. They tell where to drill holes. They even say how big the welds need to be. With this information, the factory builds the steel parts just as planned.

Accuracy and Efficiency

Getting the steel details just right cuts down mistakes and makes sure every steel part is made just how it should be. This leads to making things better, less stuff being thrown away, and building projects going more smoothly.

Quality Control

Detailed drawings allow for thorough quality checks at every stage of fabrication issues. This helps find and fix problems before the steel arrives at the site. It cuts down on the need to rework and delays in structural steel fabrication.

Enhanced Safety

Accurate structural steel fabrication ensures the structural integrity of the final assembly. It ensures proper load distribution. It also ensures proper connection points. This leads to a safe and reliable structure.

Cost Savings

Well-detailed steel structures help save time and cash by cutting down on mistakes and making the building parts process smoother. It also means less material is wasted, fewer fixes are needed, and fewer hold-ups at the building site.

Faster Construction

Detailed shop drawings are available and easy to get. They allow for smooth and efficient fabrication and construction. This leads to faster project completion times.

Manufacturing steel starts with the structural analysis. So this process goes through a lot of steps as mentioned below.

Step 1: Check the Blueprint

The detailer takes time to review the engineer’s designs, paying close attention to the listed materials and the overall plan for the structure. This careful review is key to ensuring everything is done correctly from the start.

Step 2: Model it in 3D (Sometimes)

In some cases, the detailer uses a special program to create a 3D model of the whole structure. This helps find any clashes between parts before they’re built.

Step 3: Make Shop Drawings

Using special software, the detailer creates detailed drawings for each piece of steel. These drawings show the exact size, shape, and location of holes and welds. They also include info on painting and anything else the factory needs to know.

Step 4: Double Check Everything

The detailer has detailed discussions. They are with the engineer, the manufacturing team, and other key players. This makes sure the drawings are flawless. They also align exactly with the project’s specifications. These talks are crucial for the project’s success. They ensure that the design meets needed standards and expectations.

Step 5: Build the Steel

With approved drawings, the factory uses them to cut and shape the steel parts. Then, workers take these pieces to the building site.

Step 6: Assemble the Structure

Steel building construction workers follow the drawings to put the steel pieces together, building the structure.

Structural steel offers several advantages in this regard. Steel is highly recyclable. Much of its structural steel comes from recycled content. Additionally, steel structures are known for their durability and longevity, contributing to the overall life cycle of a building.

Material Optimization

Precise detailing helps optimize steel usage, minimizing material waste during fabrication. This not only reduces costs but also conserves valuable resources.

Improved Efficiency

Accurate detailing leads to efficient fabrication and construction. This results in lower energy consumption throughout the process.

Finding a good engineering partner that uses advanced detailing software is key. They should have a team of experienced professionals. They will ensure that every project gets the highest level of attention to detail. They will work closely with engineers, fabricators, and construction teams. That’s how they will deliver clear, short, and error-free shop drawings. The drawings make steel construction efficient and successful.

Structural steel detailing is the backbone of successful steel structure projects. Choose Mold-Tek as your partner. You benefit from our long experience, focus on quality, and dedication to sustainability. We work together to ensure your steel building is strong and functional. It is also environmentally responsible.

A structural steel detailer creates detailed drawings and 3D models that guide the fabrication and erection of steel structures. They interpret engineering and architectural plans to produce accurate shop drawings, erection plans, and bills of materials, ensuring all steel components fit perfectly on site.

Structural detailing in steel involves translating design specifications into precise, fabrication-ready drawings. It includes detailing connections, welds, bolt placements, and member dimensions to ensure the steel structure is safely and efficiently assembled.

Detailing in structural engineering is the process of preparing detailed plans that specify how structural elements like beams, columns, and joints are to be fabricated and connected. It ensures that the engineer’s design intent is accurately realized in the construction process.

Structural design focuses on analyzing loads and selecting appropriate materials and structural systems to ensure safety and performance. Structural detailing, on the other hand, involves developing the construction drawings and models that specify how each component should be fabricated and assembled according to the design.

Fill out the form below to receive a sample of Wize Company’s work. This will help you better understand our quality, approach, and expertise before getting started with us.