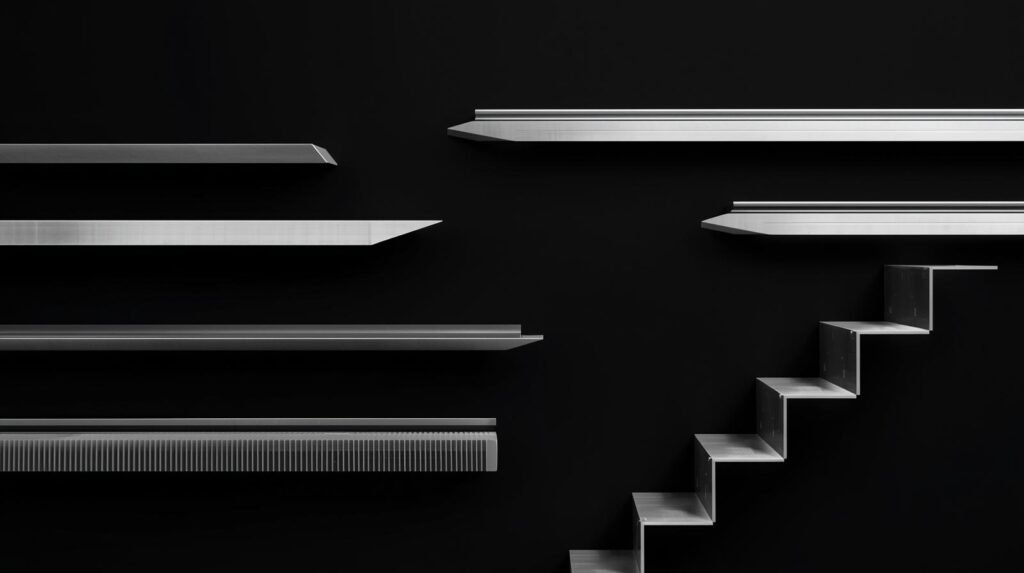

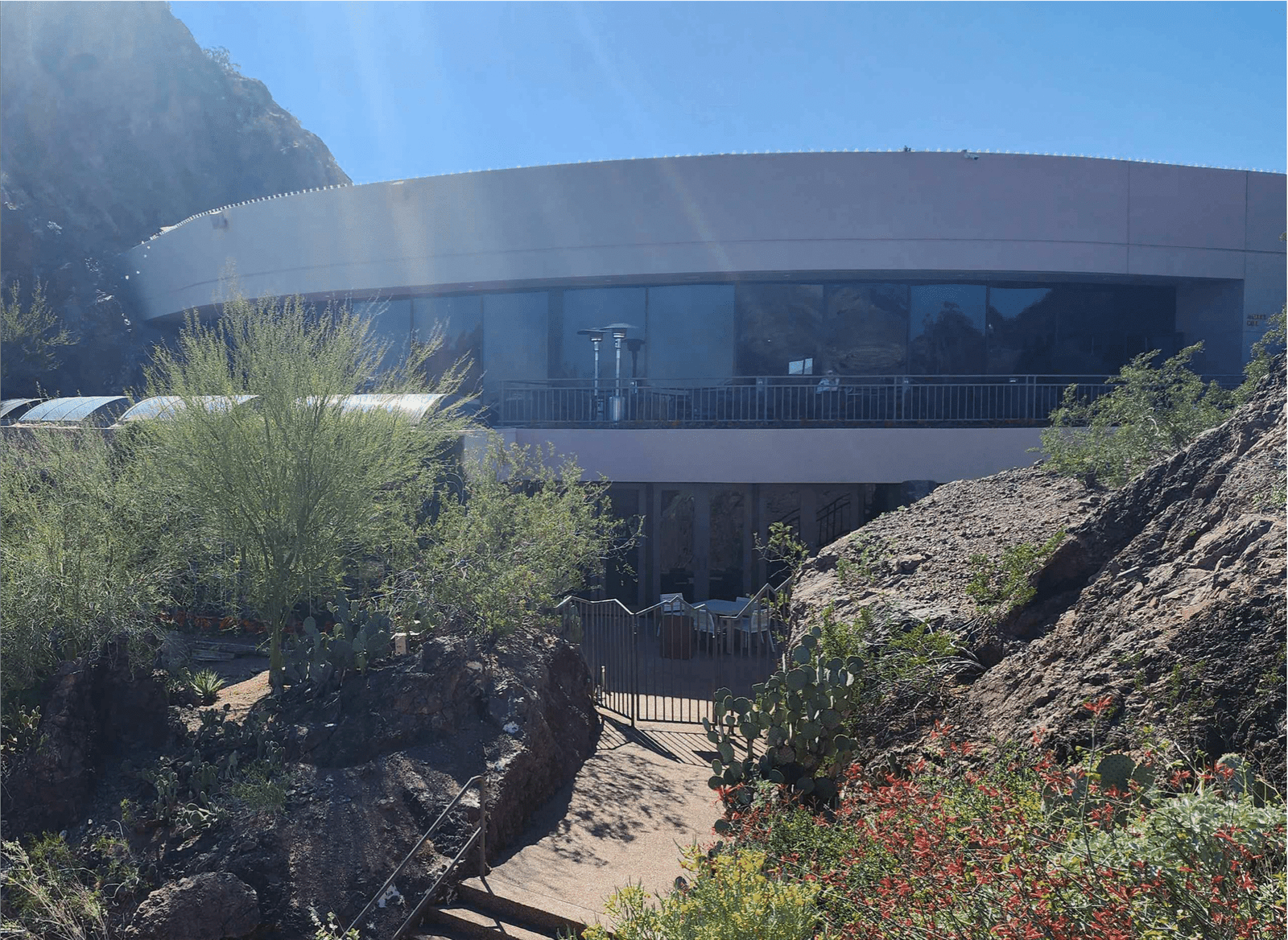

Miscellaneous steel detailing calls for a strong awareness of the design objective and the capacity to provide correct drawings and plans for fabrication and installation. Our miscellaneous steel detailing services in USA cover non-structural but vital elements, including steps, handrails, guardrails, ladders, platforms, grates, gates, and ornamental metalwork. These elements are vital for the general safety, accessibility, and functionality of a structure. Our knowledge guarantees flawless integration into bigger steel constructions, fabrication-ready plans, and exact details. Trusted by miscellaneous steel fabricators, our priorities are addressing difficult design problems, reducing material use, and guaranteeing error-free deliveries, thereby lowering rework and saving money for our clients.

Miscellaneous steel detailing involves unique challenges due to the complexity of non-structural components. At The Wize Company, we effectively manage these complexities by:

We deliver precise detailing that eliminates on-site errors, ensuring seamless project execution.

Our designs are tailored specifically to meet the unique requirements of every project.

Efficient processes enable quicker detailing, reducing overall project timelines.

Our advanced BIM integration facilitates smooth communication among engineers, architects, and fabricators.

Detailed and optimized designs significantly reduce material waste and lower overall project costs.

With extensive experience in miscellaneous steel detailing, Moldtek confidently serves diverse industry sectors, delivering tailored solutions that meet specialized demands:

We leverage industry-leading software to ensure accuracy, efficiency, and compliance in steel connection design:

Highly accurate 3D models created in Tekla Structures ensure precise fabrication drawings.

Clear, customized 2D drafting and annotation services tailored to project needs.

Complete BIM integration using Advance Steel and Revit for seamless project coordination.

Detailed, intelligent connection designs adhering to global structural codes and standards.

Detailed and accurate outputs optimized for CNC manufacturing, reducing errors and waste.

Clear field bolt and weld detailing facilitating easy and efficient on-site assembly.

Expertise in specialized detailing including stairs, railings, gratings, ladders, and platforms, tailored precisely to your project requirements.

Our steel connection detailing and validation services adhere to the latest industry standards, ensuring structural integrity and regulatory approval:

With a strong commitment to engineering excellence, our P.E.-stamped designs provide complete assurance of compliance, accuracy, and efficiency in your steel connection design, beam column steel connection, and steel column to column connection solutions.

To ensure a consistent and repeatable process, we have developed comprehensive written procedures to manage design, detailing, and deliverables throughout the project lifecycle.

Miscellaneous steel detailing involves non-structural components like stairs, handrails, and ladders, whereas structural steel detailing focuses on primary load-bearing elements such as beams and columns.

It ensures safety, accessibility, and aesthetics while complying with construction standards and enhancing overall building functionality.

Common software includes Tekla Structures, AutoCAD, Advance Steel, and SDS2, which facilitate accurate modeling and detailing.

The duration varies based on project complexity and size, typically ranging from a few days to several weeks.

Yes, our miscellaneous steel detailing services are fully customizable to meet specific project needs and industry standards.

Miscellaneous steel detailing refers to creating detailed drawings and fabrication documents for non-structural or secondary steel components in a construction project. This includes stairs, handrails, ladders, platforms, bollards, and supports. At Wize Company , our detailing ensures precise fabrication and seamless integration of these components into the overall structural framework, following international standards and project specifications.

Miscellaneous metals include small to mid-sized metal components that are not part of the main structural steel framework but are essential to a building’s functionality and safety. Examples include staircases, guardrails, gratings, pipe supports, embeds, lintels, and brackets. These elements require accurate detailing to ensure proper installation and durability in diverse construction environments.

Fill out the form below to receive a sample of Wize Company’s work. This will help you better understand our quality, approach, and expertise before getting started with us.